ASME Certified Vessel #2

This product was produced to be paired with the ASME Certified Vessel #1. This vessel was also reviewed by a third-party engineer to confirm that it meets ASME standards. This design was needed because the old evaporator was too small to be paired with the new tank design. Designing the evaporator to have the same volume as the tank ensures that the evaporator does not get overfilled at any point.

Once the new solvent tank was designed (ASME Certified Vessel #1), there was a goal to design an evaporator vessel that would be paired with it and match its volume. Here is a view of the original solvent tank vs two iterations of the solvent tank/evaporator pairs.

Here is an example of a smaller interaction that didn't make it to production.

ASME Certified Vessel #2 - Front

ASME Certified Vessel #2 - Back

ASME Certified Vessel #2 - Right

ASME Certified Vessel #2 - Left

ASME Certified Vessel #2 - Isometric Top. The two vessels were designed to have as many of the same components as possible to cut down on the unique parts needed to complete the vessels.

ASME Certified Vessel #2 - Top

ASME Certified Vessel #2 - Isometric Bottom

ASME Certified Vessel #2 - Bottom

ASME Certified Vessel #2 - Isometric

ASME Certified Vessel #2 - Isometric Sectional. The evaporator vessel design differs from the solvent tank design in that it has a fully jacketed baffled section for fluid recirculation, and it has an additional section at the bottom of the vessel to collect the final product of the extraction process.

View of the main evaporator vessel body without all the additional components.

2D Drawing of the evaporator body

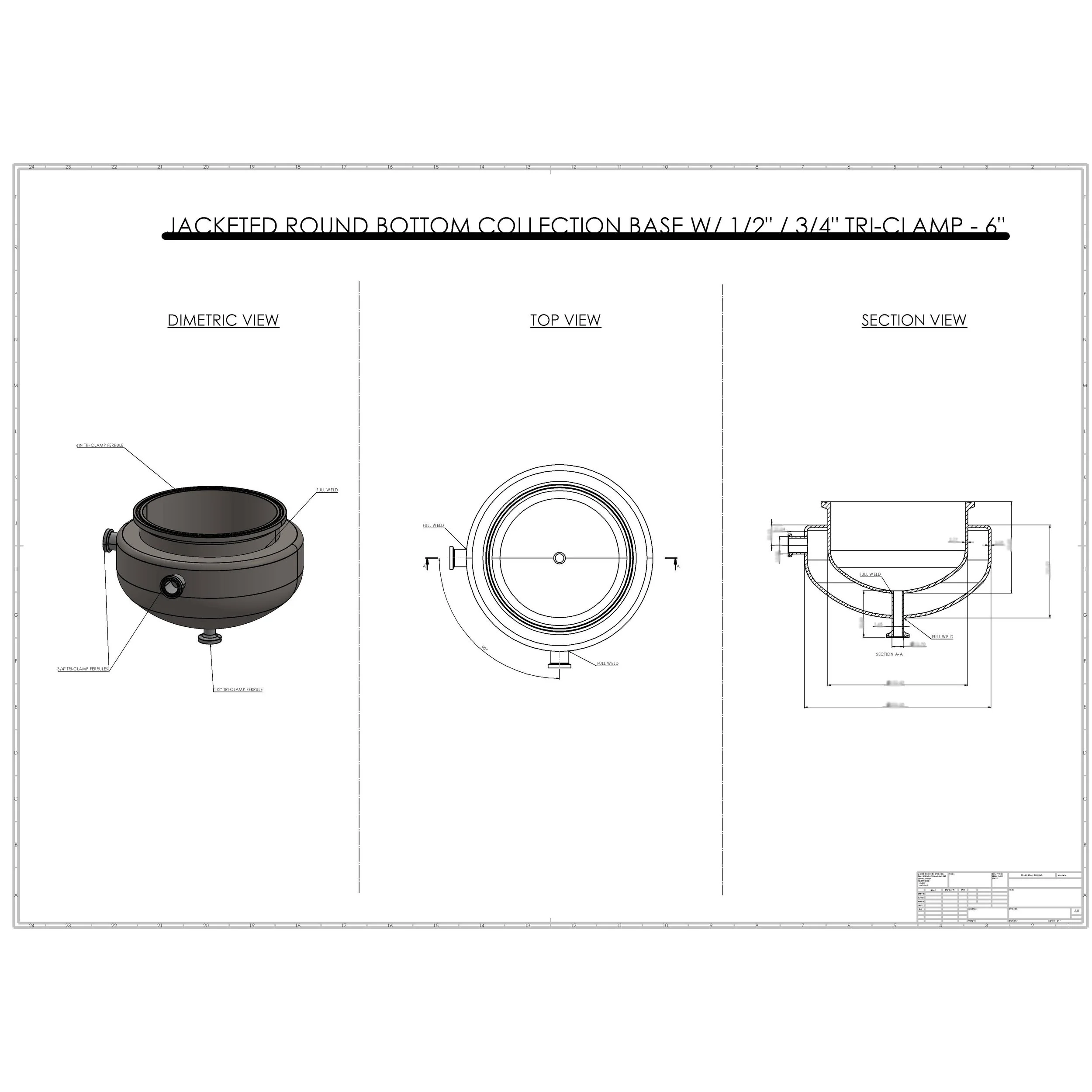

This product was a unique design needed to attach to the bottom of the evaporator. It has an inlet/outlet to match the evaporator and a 1/2" tri-clamp connection at the base, which is an ideal diameter for pouring out the final product.

2D Drawing of evaporator base

2D Drawing of evaporator shelf

The coil is an optional upgrade for the evaporator.

Why was this design needed?

Matching volume vessel to the new solvent tank

Higher pressure rating (250psi)

Increased port sizes

Addition of baffling to jacketed section

Increased diameter of the opening at the top to accommodate the coil

Mobile evaporator

What design skills were used in this project?

Sketching from standard dimensions and equations

3D sketching and creating custom planes

Volumetric calculations

Creating various configurations

Creating products that reference other parts

Sketching and modeling helix shapes

Mating complex assemblies

Render multiple views while maintaining scaling and scene settings

Producing manufacturer 2D drawings

Third-party evaluations and edits

Sourcing existing products suitable for the design

Research of evaporators

Research of baffling styles